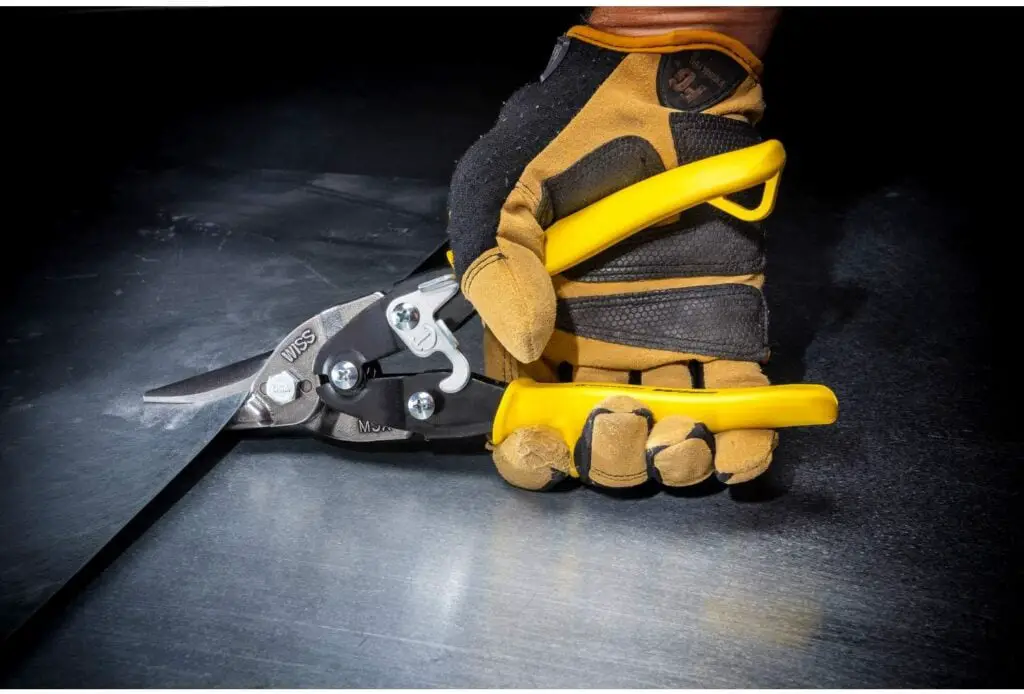

An HVAC technician needs to often slit and cut metal sheets to keep the house more energy-efficient and watertight. Depending on the metal thickness, how and where these sheets have to be cut, you would need tinners (tin snips) and aviation snips.

For ductwork and related repair you’ll definitely need these snips. We’ve assembled all the necessary information that would help in purchasing them. We’ll just give a brief refresher on how they’re used and then get into detailed reviews on some of the top snips, easing your research and purchase decision.

There is plenty more info about these 3 tin snips plus more information you should read before making a purchase. I wanted to give you a quick take in case you are running short on time.

At a Glance: Our Top Picks for Tin Snips

- OUR TOP PICK: Wiss METALMASTER M3R 9-3/4" Snips

- RUNNER-UP: MIDWEST Aviation Snip Set

- BEST BUDGET OPTION: Dewalt DWHT14676 Aviation Snip Set

Comparison of the Best Tin Snips

| IMAGE | PRODUCT | |

|---|---|---|

Our Top Pick  |

| View Latest Price → |

|

| View Latest Price → |

Best Budget Option  |

| View Latest Price → |

|

| View Latest Price → |

What to Look For in Tin Snips

If you are an avid installer or serviceman, it’s obviously more important to be careful about choosing the right snips. A poor choice of snips can lead to frequent dulling. They can also increase muscle fatigue in your hand and forearm.

Direction of Cutting

As an HVAC technician, you will need to cut, fold, shape and fit metal sheets in different sites. This is a major part of ductwork. To account for the variety of angles and special needs you’ll need to cut, you’ll need to purchase a set of snips that help you in accomplishing the work at hand.

Aviation snips or compound snips are color-coded to help the technician pick an appropriate one for the cut you need. Left offsets, also called lefts are colored in ‘red’. Though lefts are a little awkward to use (for a right-handed person), they help in a neat finish while keeping fewer fishhooks at the edges. These are used for anti-clockwise motion.

Right offsets or rights have green handles are used to cut to the right – that is, clockwise. However, if you are a left-handed, these directions would turn to be opposite.

Straights, also known as bulldogs, are used for straight and smaller cuts, instead of curves. These are normally colored orange or yellow.

Using the correct snips not only helps you get the shape but also eases the cutting process for your hands.

The best piece of advice while using snips is to have your gloves on, to avoid any fatigue onto your hands.

Longevity

For frequent snips users, this is the most important feature you need to look for. You don’t want to need to run out and replace these because they don’t hold up. Having sturdy snips is essential. Of course, you’ll still have to keep them sharpened – cutting metal isn’t easy on them. But being sure they’re not going to fall apart is key.

Grips for Metal Thickness

The right type of grip is another aspect that requires your attention during purchase. The larger the grips, the better they can handle thicker metal sheets. Tin snips maneuver well with thinner sheets made of tin and other similar metals. Aviation snips are available with larger and wider grips to accommodate the thicker sheets.

Warranty

Some manufacturers offer a warranty of more than a year if the snips are meant for heavy use. The lighter ones come with a limited warranty and shorter warranty durations.

Reviews of the Top Tin Snips for HVAC Work

HVAC technicians most commonly prefer tin snips’ sets that include straight, right and left-handed snips. But individual units are also available. We’ve examined some of the best in both cases.

Every snip is subject to wear and tear, so odds are these aren’t going to last a lifetime. But they’ve established a good reputation and shouldn’t wear out too quickly, either.

Best Overall

Wiss METALMASTER M3R 9-3/4″ Snips

Specifications

Dimensions: 9 and ¾ inches ; 1 and ½ inch cut

Blade Material: Precision cast molybdenum blades with conk ground edges and serrations

Max Gauge Steel Cutting Ability: 18 gauge steel

Cutting Options: Straight

We may earn commission from purchases made from our links, at no additional cost to you

Review

This is a straight cut tin snips that are made for professional use. It is also capable of cutting slight curves. The edges are sharp and serrated for a cleaner cut. The serration also provides a more forceful shearing action. These types of edges also maintain sharpness.

They measure 9 and ¾ inches long and have 1 and ½ inch cut. This makes cutting metal sheets faster. The jaws are non-slip and are made from tough molybdenum steel. This material is capable of holding the material firmly for a more uniform cut.

Tooth loss is also minimized thanks to the sturdiness of the steel, for a longer blade life. It is also capable of handling the stress that comes with cutting heavy 18 gauge steel. This type of snip is particularly effective at cutting low carbon cold rolled steel sheets.

The Wiss METALMASTER M3R comes with an ergonomic latch that has an operation. This allows you to use the snips whether your dominant hand is the right or left one. They are colored yellow for easy identification.

They are designed to prevent tearing at the end of a cut, by controlling the blade bypass. This minimizes both folding and burrs in the metal. It also comes with a self-opening spring, which allows for a smooth feed requiring less effort.

There have been complaints to the build quality of the snips. Most customers complained that after a few months of flawless operation, the entire tin snip came apart in the middle of work. This happened with the slightest amount of effort. The product does come with a limited lifetime warranty which may come in handy.

Wiss seems to be a winner in most cases. These can be packaged as single units or a complete set of three snips. They are made of wear-resistant molybdenum steel blades and hold up to the higher pressure from the compound lever action. It allows the cutting of material up to 18 gauge carbon steel.

Bottom Line

This type of tin snips work tremendously well on low carbon rolled steel. They are strong and sharp, with serrations designed to increase the force up to five times. They may have a short lifespan, which is something to note.

Though HVAC technicians use it multiple times, you may want to careful about the metal thickness and material you cut each time. Also, the nylon locknut may require constant rewiring.

Pros

Textured non-slip grip

Sharp edges for precise

Lightweight portable design

3 colors for easy identification

Easy to use with an ergonomic handle

These handle most materials well, including steel, aluminum, copper, plastic and any wire.

Great on straight cuts and not too harsh on the hands

Cons

Has a limited lifespan

This is a rarely-returned product. However, if you wish to do so, you may bump into an expensive return policy that is not very appealing

Runner-up

MIDWEST Aviation Snip Set

Specifications

Dimensions: 1 x 6.5 x 11 inches

Blade Material: Molybdenum alloy steel

Max Gauge Steel Cutting Ability: 18 gauge steel

Cutting Options: Right/Left offset

We may earn commission from purchases made from our links, at no additional cost to you

Review

This brand of tin snips comes as a 2 piece set. One of the snips cuts to the right while the other cuts to the left. They are color coded to make it easy to tell the difference. This design is targeted for professional sheet metal workers since it eliminates the need to buy another pair of snips.

This is also evident in the build quality of the snips. The blades are made from forged molybdenum alloy steel. They are austemper treated with heat to increase durability. The handles, on the other hand, are made from high tensile steel which is resistant to bending. They are designed to provide compound leverage when in use. This multiplies the pressure exerted by the hands by 8 times. This reduces the fatigue that comes with dealing with large metal sheets.

It also reduces the chances of injury to your arm from overworking certain tendons and joints. The handles also come with Kush N Power Grips. These shape themselves into the motion of your hand when cutting. They have indented ribs, which prevent the hands from slipping. The sure grip also reduces the chances of injury.

The tin snips are made and assembled entirely in the USA. This is something to note for the conscious buyer. There have been complaints about the size and weight of the product. They measure 11 inches and weigh about 1.94 pounds each. This makes them heavy and unwieldy to use. They have also been known to break down in a peculiar fashion; only one of the snips is affected. The other one continues to work normally.

This particular option from Midwest Tools includes the right and left snips. It’s a respected brand that continues to deliver. Their “KUSH’N-POWER grip” is ribbed to prevent slipping and a bit softer. It also is contoured for your fingers (assuming you have “larger” hands).

Bottom Line

This is one of the best products that the Midwest has to offer. They have sharp blades and the compound leverage makes the work easy. They are heavy however and this might make using them more work than it’s supposed to be.

Pros

Locally assembled

Strong and durable build

Comfortable grip

Designed to reduce fatigue when cutting

Blade tip is well-made and allows precision cuts, reducing cutting strokes. The composition of the blades helps assure maximum blade strength.

Cons

Bulky and can be hard to wield

If you have small or average hands, then you may want to consider another option. But this is a great product from a quality perspective

Best for the Money

Dewalt DWHT14676 Aviation Snip Set

Specifications

Dimensions: 11.3 x 15 x 7.7 inches

Blade Material: Chrome and molybdenum steel alloy

Max Gauge Steel Cutting Ability: 18 to 22 gauge steel

Cutting Options: Right/Left offset & straight

We may earn commission from purchases made from our links, at no additional cost to you

Review

The Dewalt DWHT14676 Aviation Snip Set comes with the patented flush hardware. This design allows you smooth access from the pouch. It is designed with a long life in mind, and this is achieved thanks to the pivot bolt. This is made to be 25% larger than most of the competition. There is an internal locking mechanism which also incorporates an auto-release feature. All these make them easy to use.

They are made from forged chrome and molybdenum steel alloy. This is designed to be stronger than most of the completion by as much as 55%. The end result is a blade that is capable of maintaining a sharp edge for longer.

It is also capable of cutting through larger and thicker sheet metal. The product comes as a set of three tin snips. They are color coded to make it easier to identify when working. The handle is designed to be comfortable and fit better in your hand. It is also non-slip to reduce the chances of an accidental injury in the workplace. These tin snips come with a 90-day return window for any defects or breakages during shipping. They also carry a limited lifetime warranty from the manufacturer. There have been complaints about the breaking down of one of the tools in the set.

Comically, the rest of the items continue working fine. The blades are also considered on the smaller side, with a limited cutting range. This means that you take longer to cut through a single sheet of metal than some of the competition. The smaller cutting range, however, make them ideal for tiny precision cuts.

Bottom Line

The collection of useful features at the price point is what makes these the best budget snips in the market. The comical breakage of only one of the tools is something you may want to note.

Pros

Comes as a set

Long cutting life

Easy grip handles

Limited lifetime warranty

Color-coded for easy identification

Cons

One of the tools in the set always breaks down

Stanley FatMax 14-563 9-7/8-Inch Straight Cut Aviation Snip

Specifications

Dimensions: 9.06 x 1.18 x 7.48 inches

Blade Material: Chrome molybdenum steel

Max Gauge Steel Cutting Ability: Up to 18 gauge (1.2mm) cold-rolled steel or 23 gauge (0.7mm) stainless-steel

Cutting Options: Straight

We may earn commission from purchases made from our links, at no additional cost to you

Review

If you want a single straight-cut snip, then here it is. It comes with good bi-material cushion grip and ensures that there is no slip while using it. This is best for compound cutting for cuts of up to 18-gauge steel. It also has limited lifetime warranty.

Pros

Excellent for cutting tin or steel, can cut wires, as well

Cons

Be careful while using this for thicker sheets. It’s not always particularly great on heavier materials

Best Right Angle Snips

Milwaukee 48-22-4021 Right Angle Snips

Specifications

Dimensions: 5.5 x 12.8 x 1.4 inches

Blade Material: Forged Alloy Steel Blades

Max Gauge Steel Cutting Ability: Up to 24ga CRS (Cold Rolled Steel) & 28ga SS (Stainless Steel)

Cutting Options: Left cutting

We may earn commission from purchases made from our links, at no additional cost to you

Review

This is a lightweight pair of tin snips that are specifically designed for making right angled cuts. The blades are made from forged steel alloy to maximize strength and durability. They are coated with chrome to protect the blades from rust.

This also gives them a longer cutting life. The jaws are serrated which gives the tool an aggressive shearing, making the cutting of large sheets of metal easier. The serrated jaws also mean cleaner cuts with less margin for error. These snips come with two patent-pending design features. The first is a flush bolt design which prevents the tool from catching on the material during the cutting process. This lessens the chances of tearing at the end of a cut and also extends the life of the snips.

This is because accidental damage from catching on the material is reduced. The other feature is the one-handed locking. This allows you to open and close the snips with ease. The handles are made from hardened steel and come in an ergonomic design. This comfort grip protects the tendons and joints in your hand from injury during rigorous operation.

The snips are designed to cut through 24 gauge cold carbon rolled steel, and 28 gauge stainless steel. They do however tend to break down after a few months of use. One notorious part is the one hand locking mechanism which stops working after some time. The product comes with a lifetime warranty for manufacturer’s defects.

This set from Milwaukee includes all 3 types of snips: right, left and straight. The set includes a wire cutter and is known for high durability. It has steel blades plated with hard chrome for rust protection. It is also has a compact design with ergonomic handles for tight spaces. The manufacturer provides limited lifetime guarantee.

Bottom Line

This the ultimate tool for cutting sheet metal at right angles. The jaws are strong enough to cut through 24 gauge low carbon rolled steel.

Pros

Strong and durable design

Quick opening and closing

Does not catch on material

Lightweight and easy to handle

Lifetime warranty against manufacturer defects

Beginners are very happy with it

Cuts sheet metal well and is also designed to cut aluminum, vinyl siding, screening, cardboard, leather, and copper

Cons

Tends to break down after months of use

The locking mechanism in these snips is a little messed up and is a turn-off while using them on field

When and Where an HVAC Tech Uses Tin Snips

While working with ducts – and with flashing or gutters if you go beyond HVAC – you are bound to search for snips in your toolbox. Tin snips are used to cut metal sheet in simpler cases and work pretty much like scissors. Aviation snips, as the name suggests, were developed to cut metal in the aviation manufacturing industry, but are still often used by HVAC techs and other tradespeople.

Visually, there is a subtle variation in design between tin snips and aviation snips, but the functionality varies while in use. The terms are sometimes used interchangeably, but they come with a difference in design, functionality and utility.

Tin Snips

Regular tin snips are best for long and straight cuts. There are also duckbill snips, used to cut sharper curves than the regular ones. Duckbill snips, however, cannot handle the same thickness as regular tin snips.

The blades of tin snips would need timely sharpening.

To cut round ducts, tin snips are the most comfortable option. They allow the versatility to make the cut you need. However, if the thickness increases, technicians switch to using a compound snip to cut the metal strip.

Aviation Snips

Aviation snips are designed to reduce the force necessary to make cuts, which helps reduce user fatigue. They are spring-loaded and come with a hook lock to keep them closed when not in use. Aviation snips cannot make long cuts like tin snips but are designed to make better curves and change directions.

Straight-cutting compound snips work best for cutting thick or doubled-up sheet metal. They can generally handle up to 18-gauge mild steel. To tackle difficult cuts, technicians combine both right- and left-handed snips. Compound snips are not meant for straight cuts for the most part. However, if you choose to use them, then open and close the jaws fully with each stroke to maximize the length of the cut.

Curve-cutting snips are used to cut the metal sheet in a rounded shape.

People Also Ask

Making an informed decision when it comes to purchasing tin snips is about information. In the market today, there are over a dozen types of tin snips and this can be daunting to a new shopper.

There are several factors to consider when choosing which type to get. Some of these include the type of metal sheeting being cut, the type of edging you desire, and the overall usage of the tin snips. People also ask different types of questions to help them better understand the subject. Some of these include:

The short answer is that tin snips are scissors for metal work. They resemble scissors but are much stronger, and let you make very precise cuts. They look different depending on the purpose, but all have the universal short blades with the long handles.

This design allows you to cut through the hard metal using the least amount of effort possible. They also usually have wider jaws than on normal shears in order to allow for more precise cutting.

Just like every tool in your shed, you need to carry out maintenance on your tin snips. It is important to note that not all tin snips can be sharpened. Ground edge snips can be sharpened, but working on snips that have serrated edges will ruin them.

To sharpen tin snips, start by cleaning all the dirt and debris with a dry cloth. You then open the blades as wide as you can or even separate them from the bolt. The third step is to sharpen the blades using a metal file, in a single direction from the pivot headed towards the tip. The file should be angled so that it only acts on the slanted edge and not the whole blade. Finish the process by polishing the edge with a wetted whetstone.

You can use tin snips to cut through metal roofing in the following simple steps:

1. Choose the right snips. Depending on the size of the metal sheet and the type of cut you are aiming for, you may have to use more than one pair.

2. Place the metal roofing sheet within the blades of the snips. Make sure to open the blades as far as they can go for this step. It will make cutting easier.

3. Position the snips so that the flat part of the inner blade is parallel to the edge of the sheet. This will prevent you from making a bent cut.

4. Make sure the snips are upright. This should be held throughout the cutting process, to prevent damage to the tool.

5. Start cutting by squeezing the handle. Make sure that the jaws don’t close fully. This will leave dimples in your metal sheet.

6. Make sure to hold the metal away from the cutting. This will prevent injury to your hand or even damage to the snips.

Tin snips have two major parts; the handles and the blades. They are both forged differently. The blades are supposed to be very strong so as to cut through metal without bending or breaking. They are made from drop forged steel. Forging steel makes it harder and stronger than most of the metals that make sheeting. They are then treated with heat in a process called hardening and tempering.

The handles are made from forged steel as well. What makes them different is the coating. Some have simple paint, which can be laid bare by common wear. It is also affected by temperature and humidity. Another type of coating is bi-material. Most of them use a variation of plastic and rubber to give the snips both grip and comfort.

When going shopping for a pair of tin snips, you may notice that they come in different colors. Typically, they come in either red, yellow, or green. The colors are not random and each means something different. Green means the snips can only cut right and red snips cut to the left. Yellow snips, on the other hand, can cut to the left, to the right, and straight.

Conclusion

Though tin snips are scissors look-alike, they are specially designed to cut thick metal sheets. To keep your hands safe, ensure that you use the correct pair of snips for a given thickness and the type of cut you’ll be making. While not all HVAC technicians require heavy-duty snips, it’s always good to outfit yourself with quality tools that won’t let you down.