Stunningly and ironically, duct tape isn’t approved for duct work. If you’re a professional in the HVAC field, you already know that. For everyone else, it’s probably a surprise. This article will help you to choose an appropriate tape or mastic that best accompanies your sealing work over HVAC systems.

We are going to talk here about some basics about HVAC tapes and mastic with a brief purchase guide that will help you choose a product that will meet your needs.. The details would include:

- The distinction between foil tape and mastic

- Factors To Consider in Choosing a Tape

- Authenticity of duct tape

- Best HVAC tapes

- Best Mastic and mastic tapes

At a Glance: Our Top Picks for HVAC Tape and Mastics

- OUR TOP PICK: Professional Grade Aluminum Foil Tape

- Aluminum Foil Tape - Professional/Contractor-Grade

- BEST BUDGET OPTION: Duck Brand 673753 HVAC UL 181B-FX Listed Foil Tape

Comparison Chart of the Best HVAC Tape and Mastics

| IMAGE | PRODUCT | |

|---|---|---|

Our Top Pick  |

| View Latest Price → |

|

| View Latest Price → |

Best Budget Option  |

| View Latest Price → |

|

| View Latest Price → |

|

| View Latest Price → |

|

| View Latest Price → |

|

| View Latest Price → |

Foil Tape vs. Mastic

A good tape or mastic is essential to make HVAC systems more energy efficient by avoiding leakage. Leaky ducts can result in increase in heating and cooling costs. Energy efficiency can be ensured by choosing well between mastic and foil tape for your leakages.

Mastic

Mastic is preferred for HVAC leakage repairs and duct work because it is easy to apply in unreachable nooks. This gooey substance can be applied using a paintbrush. There is no fear of the mastic stripping off, keeping the ducts leakage-proof. This is the best option if you need to seal HVAC systems with dusty and irregular surface.

Mastic also comes in the form of tapes made of aluminium foil. Mastic and mastic tapes stay strong even on moist and gutter areas. It can be used for both indoor and outdoor purposes.

Professional Grade Aluminum Foil Tape

Foil Tape

Foil tape wins over duct tape in many aspects because of its strength. But mastic is preferred over foil tape as it can be applied on all surfaces. High.quality foil tapes seal and work for more than a decade in many cases. They can function in humid and low temperatures without any concern of peeling off. It is greatly preferred to seal heating, air conditioning and refrigeration systems. It’s often used for insulation, seaming and patching work.

Over the course of years, both these materials have been improved in strength and so are used even for smaller and domestic HVAC system repairs.

Review of the Best HVAC Tapes

To help you avoid the hassle of searching, we have researched and listed 4 foil HVAC tapes that can help you in fixing HVAC ducts. While you could have a very specific need for which the following may not be the best solution, these can come in handy for the majority of ductwork.

Best Overall:

Professional Grade Aluminum Foil Tape

PROS

CONS

There are certain characteristics that you look for in a good HVAC tape, and the Professional Grade Aluminum Foil Tape has these ticked off. It measures 2 inches by 70 yards, which is approximately 33 percent longer than the competition.

It makes it ideal for HVAC repairmen who have a lot or work orders and might take time to replace some of their tools. The tape is coated with a nice silver finish, which blends in with most HVAC systems and their colors.

It is resistant to moisture, flames, most household chemicals, and mold. It is also resistant to UV rays and works well in any type of weather. This makes it ideal to use even on outdoor air conditioning units. It does not fade or become brittle due to exposure to the sun.

It is also designed to stick to most surfaces which makes it ideal for someone who deals with different types of AC units. It is also designed for sealing different types of cold and hot intakes including HVAC air ducts.

The manufacturer guarantees that the product will work perfectly, and guarantees a full refund if you are unsatisfied with the product. There have been a lot of positive reviews from the customers praising the product.

Complaints have however been leveled against the thickness of the product. Most of the complaints have stated that the thinness of the tape makes it hard to use, and rips at the tiniest provocation. This leads to a lot of wasted tape, especially if you are working cramped spaces.

Bottom Line

This is a tape that has received good reviews online especially about its ability to stick to various surfaces. They have extensively marketed as being longer than most of its competitors.

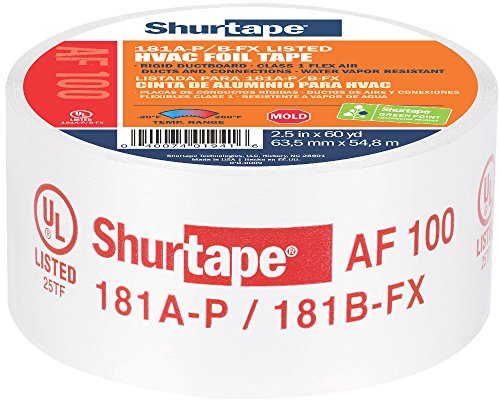

Runner-up:

Aluminum Foil Tape - Professional/Contractor-Grade

PROS

CONS

This is an industrial grade aluminum foil whose biggest selling point is that it sticks to anything even at both temperature extremes. It is capable of performing perfectly at low temperatures of -20 degrees Fahrenheit, and heats of up to 220 degrees Fahrenheit. This is very useful for AC units that work over long periods in both the winter and the summer. The tape is able to withstand constant exposure to heat or cold.

It has a wide variety of uses including in sealing aluminum, general HVAC repair, use in duct insulation, and the temporary repair of various surfaces such as wood and metals such as copper. It is also used in the sealing of cold and hot air ducts. This tape is also conductive and helps in marginally increasing the cooling and heating efficiency in your air conditioning unit.

It comes with conformable backing, which gives the tape will stick to both smooth and uneven surfaces equally. This is important if you are working in spaces that have debris or in dusty conditions outside.

It is important that you make sure the surface you are using is clean and dry. Remove and wipe off any grease or oil, as these will impair the sticking ability of the tape. There have been complaints that it has problems sticking to surfaces like wood and plastic.

It has also been said to be hard to remove once it gets stuck, which can make subsequent repairs annoying. It can also leave stains on your air conditioning unit. The manufacturer states that the tape should work perfectly if it is used in the conditions stipulated by the instructions on the packaging.

Bottom Line

The Aluminum Foil Tape - Professional/Contractor-Grade is a great tape that has various uses. It is important to note that the tape may not work as advertised on certain surfaces and that it can be hard to remove in subsequent repairs.

3. Duck Brand 673753 HVAC UL 181B-FX Listed Foil Tape

PROS

CONS

This product receives high marks all the way around. It is a UL181B-FX listed silver adhesive tape approved for use on flexible air ducts and is rated for resistance to flame and smoke. It’s made to work in temperatures ranging from -10 to +210-Degree (Fahrenheit).

It works for both indoor and outdoor use and is ideal for sealing both cold and hot air ducts. Each roll of Duck Brand HVAC Foil Tape is 1.88 inches wide x 120 yards long.

One word of caution is you need to use this tape on a clean surface. Also, it’s a rather thin tape. If you personally prefer something thicker, this might not be the product for you.

At 120 yards, this tape is longer than most of the competitors in the market. This makes this tape last longer as a result and is ideal for people who work extensively on HVAC on a daily basis. It is also ideal for large repair jobs

The biggest selling point is the adhesiveness of the tape, which is guaranteed by the manufacturer’s extensive experience in adhesive products. This makes them ideal for various uses other than HVAC repair, including duct sealing and some aspects of metal repair.

The tape has a relatively high range of operating temperatures, starting at -10 degrees Fahrenheit up to 210 degrees Fahrenheit. It allows the bonding agent on the tape to remain active under extreme temperatures and makes this ideal for working both indoors and outside. This is one of the best tapes to use with flex duct. This is because its thinness allows it to conform to the insulation jacket, which is different from aluminum tape. Aluminum tape pushes the jacket out of shape instead.

A point of note is that this tape is thinner than most customers expect. This is important if you are going to be working on surfaces that require thicker tape. The strength of the taps is however not compromised.

This means that it can be used successfully to plug loose HVAC joints. It even sticks effectively to fiberglass and tin. To use this tape, make sure the surface is clean and devoid of debris and dust. It is also reasonably priced as a flex tape, and the 120-yard length costs the same as 50 yards of aluminum tape.

Bottom Line

The Duck brand has been in the adhesive industry for a long time. This has translated to how well it sticks to surfaces, and to a more diverse range of materials.

4. 3M Silver Foil Tape

PROS

CONS

3M offers us another highly-esteemed tape that is used widely. It measures 2.5 inches wide x 50 yards and has an acrylic adhesive. Some of the features that you can look forward to with this tape are resistance to flame, moisture, weather, UV degradation and chemicals. Also is a thermally conductive tape for heating and cooling efficiency with heat reflectives.

This is a UL 181 A-P and UL 181 B-FX listed tape with printed backing for HVAC systems. The only turn-off could be that the backing has red words on it and hence could make your tape work a bit too obvious.

This is a superior quality industrial grade tape. It has one of the widest working temperature ranges in starting at -40 degrees and going all the way up to 300 degrees Fahrenheit. This gives it an edge over the competition when it comes to application, with the 3M Silver Foil Tape being used in multiple industries including aerospace and automotive. It has also been used in the defense and marine industries with various applications such as electroplating, harness wrapping, damping vibrations, seaming, and even shielding.

This is an incredibly durable tape that will serve you for a long time. This comes from the ability to resist wear and tear from the elements including moisture, chemicals, and the dreaded UV degradation. It is this quality that makes it ideal for outdoor applications such as HVAC repair and seaming. Since it is incredibly sticky, it is capable of withstanding vibrations from the ducts and pressure from the vents, where other tapes would fall off.

It is important to note that this foil tape is significantly shorter than the competition, measuring only 50 yards. This has been a point of concern from some customers, who have had to buy a new roll more often.

It is also important to note that the manufacturer has a disclaimer stating that the product is packaged for sale to, and use by, industrial and commercial consumers. This means that it is not packaged for sale to an individual in the general public.

Bottom Line

This is a superb tape whose only drawback is that it is short. Given that this tape is designed for use in commercial and professional settings, it might be a pain to keep purchasing new rolls.

Best Duct Sealing Kit:

No. 7 Mastic Premium Air Duct Sealing Kit

PROS

CONS

No. 7 offers this gray-colored, 915ml container of mastic that comes with an entire application tool kit. Apart from the mastic itself, the kit includes a brush, flashlight with batteries, can opener, red shop towel and black burlap bag.

This comes with a 12-month warranty. It is a water-borne air duct sealant, used for permanently sealing the fabricated joints and seams of sheet metal air ducts, rigid fiberglass air ducts, flexible air ducts and thermal insulation.

This is your best bet when it comes to fixing leaks in your air conditioning system. This premium sealant is used to seal seams and joints in fabricated metal air ducts, fiberglass air ducts, and flexible air ducts. It can also be used on thermal insulation, and crawl space vapor retarders. Sealing any leaks that could come through “torn” seams lead to reduced performance, which translates to reduced air quality and increased energy usage.

To apply the No. 7 Mastic Premium Air Duct Sealing Kit, make sure that the intended surface does not have any algae, corrosion, fungus, mold, or any other type of debris. The important part to note is that you do not thin this product at all. Once the surface is to the intended standard, apply a 25 mil thick tack coat, using either a brush, trowel, or the palm of your hand. If you are using a fiberglass mesh, this is when you embed it into the tack coat. Apply a finishing coat that is another 25 mil.

There are some precautions to note when using the product. Make sure to use it in a well-ventilated space with proper lighting. This reduces the chances of injury and lets you breathe freely. You should also use the product between 38 and 120 degrees Fahrenheit, and in low to medium humidity. High humidity retards the drying process. It is also important to note that if you or any member of your family have any allergies or respiratory tract ailments, you should consult your doctor before applying this inside your Air conditioning unit

Bottom Line

This is a superior grade sealing kit that does the job it was meant to do with minimal fuss. It is, however, important to note that this is an application product, and may be unsuitable to people who are looking for a quick fix. The results are permanent.

Best Mastic Tape:

Intertape Polymer Group MF2100 Silver ALF Butyl Mastic Foil Tape

PROS

CONS

This is a mastic tape that looks like a thin malleable foil coated on one side with a thin extremely sticky clay material. It is designed with general HVAC applications, maintenance, and repair in mind. In this regard, the tape sticks particularly well on sheet metal, duct board, PVC coated duct, and even wrap vapor barriers.

When used, it provides an instant waterproofing grip to various different materials. It achieves a full bond in 24 hours. This makes this product excellent for use on outdoor units as well. The quality makes it last for years after application. You should, however, make sure to press firmly on the tape when applying.

The Intertape Polymer Group MF2100 Silver ALF Butyl Mastic Foil Tape is designed to include a release liner. It is also incredibly flexible and can be contorted to fit different surfaces without cracking, even after months of use. The modified butyl adhesive is pressure sensitive.

All these combine to make this one of the easiest tapes to use in the market. Another very useful feature is that it is paintable. This means that once you are finished with your repair, you can repaint over the tape to make it blend into the surrounding material.

The tape is also resistant to degeneration from weather such as cracking after continuous exposure to the sun. It does take some time to get used to, but the instructions are clear and precise. Some customers have had to experiment on a dummy surface at first application. There have also been complaints about the width of the tape, with most expecting it to be wide enough to cover sheet metal screws.

Bottom Line

The uses for this tape in HVAC repair and maintenance are extensive. The instant waterproofing and being paintable are excellent qualities. It does have a small learning curve before you can use it effectively.

7. United States HDW KK0326 Duct Seal

No products found.

PROS

CONS

United States HDW offers this duct seal that’s known to work great in combination with a foil tape. It’s a great hardware glue for duct joints. It’s an easy-to-use paintable sealant that is water based and fiber reinforced.

This product is best for sealing connections on flexible duct or fiberglass duct board. It is crack- & peel-resistant, mold & mildew resistant and great for both indoor & outdoor use. It is UL Listed 181A-M/B-M and LEED Qualified. However, if applied in thin layers it may get brittle. So don’t try to skimp on application!

This is a water-based duct sealant that is designed for use on both high and low-pressure systems. It is this flexibility that makes it a darling for many HVAC repairmen. It is made entirely in the United States, for use in both commercial and residential settings.

It is a premium quality water based product that is fiber reinforced for increased durability. It is also resistant to cracking and peeling, mildew, and mold. This means that it can be effectively used both indoors and outside.

It has multiple applications in the HVAC industry, including sealing joints and seams, as well as duct wall penetrations on metal air ducts. It is recommended by most HVAC professionals for sealing the connections for fiberglass duct boards. This is because it is incredibly sticky and holds its adhesiveness for a long time after application.

Being water-based, it is safe for the environment. It also improves the working of your conditioning unit by completely sealing off all the leakages. It has been touted to be better than most of the other options in the big box stores.

There have been complaints that the product tends to become brittle and break away after exposure to the elements. This is however when applied in a thin layer. It requires to be generously applied for the best results. This can be a problem for professionals since it means you will have to constantly have to purchase replacements. There is also a lack of extensive customer reviews which would go a long way to give user feedback.

Bottom Line

This is a high-quality duct seal, but if you are using it, make sure to use generous portions.

8. Intertape Polymer Group 5010 Aluminum Foil Tape

This is a UL-181AP and UL-181 B-Fx rated product for ductwork. This aluminium foil tape has a great backing, making it easy for identification and inspection. This is an acrylic-based pressure-sensitive adhesive combined with the conformability/flexibility of biaxial-oriented polypropylene (BOPP) film.

It provides superior sealing, protective benefits, and ease of handling. Some features of this tape are that it is flame retardant, has high shear, and is UV resistance. It also has superior bonding at sub-zero and at elevated temperatures. The best part is that it maintains vapor barrier integrity.

We have this Shurtape product on our list because it is a 5-star HVAC tape and is preferred for its tack and adhesiveness.This is a UL 181A-P/B-FX-listed aluminium foil tape that comes in a roll 2.5 inches wide and 60 yards in length.

It is lined and backed for identification. It is great for for joining and sealing joints, connections and seams on rigid fiberglass duct board and flexible air duct.

The best part is that it is engineered to form airtight bonds on joints and seams in application temperatures ranging from -20 to 260 degrees Fahrenheit as well as in humid conditions. }

10. Hardcast Rolled Mastic Duct Sealant

Hardcast mastic tape, used as a sealant, has little to nothing going against it. This is a great home improvement tool for DIY kitchen and dining hacks too. This foil grip sealant is best for duct joints and is pressure-sensitive for a 40-year cycle. It’s also water resistant on most surfaces.

11. Intertape Polymer Group Mf2100 Silver Alf Butyl Mastic Foil Tape

This mastic tape from Intertape is considered to be a great sealant tape. It has a Butyl foil tape and comes in a 100 feet length. It can withstand temperatures between -20 to 200 degree fahrenheit.

It is ideal for replacement applications and other general-purpose duct joint and HVAC applications and is tested in accordance with UL-723 seal. It’s also a LEED point contributor for “green” applications.

It provides an instant waterproof grip to a variety of surfaces and a full bond in 24 hours. It is highly resistant to the effects of weather, UV, temperature, mold and mildew. It’s also paintable!

Factors to Consider When Choosing Tape

Choosing the right kind of tape for duct work can be tricky. The following guide will help you to purchase the right type of tape for this purpose. Some factors that you need to look for are explained here.

Backing

Tapes are backed by a film that provides good electrical insulation and protection. This is a critical feature to consider when seaming work is undertaken for house wrap or insulation. It indicates to the technician which side of the tape has the adhesive. The tape could have a backing made of film, cloth or foil. It is not meant only for aesthetic appeal but is also used to protect the adhesive on the other side.

Adhesive

While backing constructs one side of the tape, adhesive forms the other. Choose your adhesive based on the type of working you’re doing. Its relevance is determined by its stickiness, durability and usage. Adhesives could be made of rubber, acrylic or butyl.

Rubber adhesives offer good tack and adhesion but do not perform well below the freezing point of 32 degree Fahrenheit. Butyl on the other hand makes a good rubber adhesive, but also performs well in extreme temperatures and preserves good flex qualities. Acrylic adhesives offer a good balance of adhesion, shear and tack, with good resistance to thermal and UV degradation.

Permeability

This is a factor that keeps the air from leaking out. With air-tight tapes comes less permeability, ensuring less or no leakage. You need to be looking for zero permeable tapes. These are typically supported well by acrylic adhesives.

Adhesion

Adhesion is the ability to form a permanent and strong tack onto the surface. A strong tack prevents the tape from rolling up or flagging during installation. Tape should also have a good initial quick stick.

Conformability

This determines the ability of the tape to be pressed around irregular and non-smooth surfaces.

Tack and Strength

Tack is the ability of the tape to stick immediately upon application. It also shows the strength of the tape to hold different applications and material.

Code Compliance

Using tapes that are code compliant is essential to pass inspection. It’s important to adhere to necessary safety measures and the quality required work on HVAC systems. In this context, UL listings are critical.

UL Listing means that UL has tested representative samples of a product and determined that it meets UL's requirements. Depending on the task at hand, you’ll need to be sure that the adhesive is appropriate and approved on the UL listing.

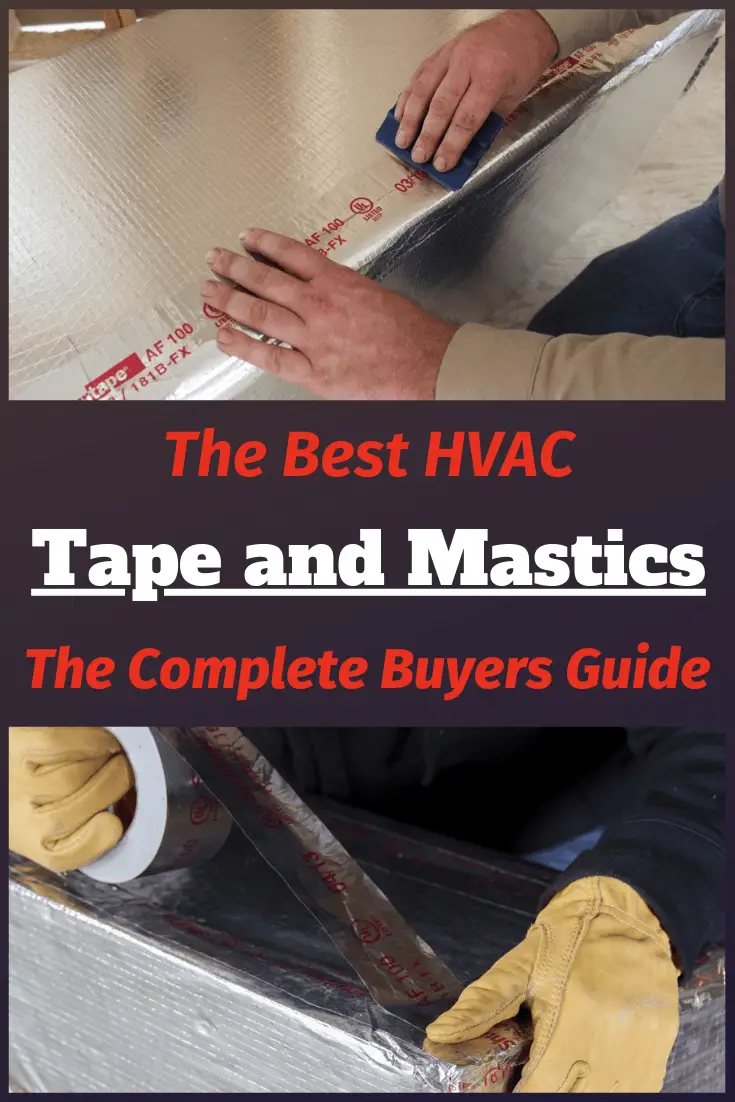

Application Technique

HVAC tapes are pressure sensitive and hence the technician needs to adhere to the respective application technique. Implementing the right application technique ensures that the adhesive is intact and the tape works its best. The optimal tool that will provide the right pressure to create a permanent sealing with the tape is a squeegee.

But… Shouldn’t Duct Tape Work On Ducts?

Note that the term ‘duct tape’ is very misleading in this context. Duct tape is neither recommended nor approved to seal or stop leakages. If you intend to use duct tape, it will not be a permanent solution for your leak.

Since duct tape is normally made of cloth or scrim-backed pressure-sensitive tape, it does not seal leakages well in high temperatures. HVAC systems are constantly exposed to wide range of temperature variations. That makes duct tapes susceptible to become brittle and chipping off after a short amount of time.

Lab tests and research have also confirmed that duct tapes produce toxic smoke when exposed to heat. They do not carry any safety certifications such as UL or Proposition 65.

Conclusion

For those working constantly with installing or sealing leakages in HVAC systems, you’ll always have eed for foil tape and mastic. Foil tape is generally preferred over mastic or mastic tape. But when you work on larger projects and need to evaluate your expenses, you may have to consider one over the other to suit your budget. At other times, there is a need to use a combination of both to deliver a clean and qualitative result. Both serve their purpose and both have their place in duct work. Just remember - no duct tape.

People Also Ask

There are certain things you should know before you purchase HVAC tape. If this is your first time, or you are looking for an alternative HVAC tape, looking though frequently asked questions. These usually cover a wide range of topics including who to use foil tape and what to use it for. Here are some of the questions most asked:

What is Aluminum Foil Tape and What is it used for?

It is an environmentally friendly material that is used for thermal insulation. It is lightweight, soft, and easy to install. It has the structure of aluminum foil and varying degrees of adhesiveness depending on the manufacturers. It has been used in various industries including HVAC maintenance and repair, thermal insulation in the automotive industry, and for various uses around the home.

What Kind of Tape Do You Use for Ductwork?

There is a misconception that duct tape is used for sealing HVAC ducts. This is wrong and could cost you a lot of money in energy waste and subsequent repairs. There are certain products that are designed for duct sealing and these include

Duct Mastic

This is a gooey material that is applied to seams as a sealant, using a putty knife or a paint brush. It is used in conjunction with fiberglass mesh.

Foil Tape

This is best used on heating ducts because the metal backing gives it resistance to temperature changes.

How Do You Remove HVAC Tape?

The removal of HVAC tape is a multi-step process. The first step is to slide a straight razor under the desired edge until you lift a tab that is separated from the material it was adhered to. The next step is to fold the edges of the tab towards the middle in a triangle shape.

Push down on the duct foil tape that is still stuck to the material. Pull up on the tab slowly to remove the tape. You then spray the area with an industrial strength cleaner. Make sure to wear safety equipment for this part. Finally, clean the area to remove all the residue.

Is HVAC Tape Waterproof?

The short answer is yes. HVAC tape manufacturers understand that there exist outdoor HVAC units. As a result, most HVAC tapes are made to be water resistant. They are also made to be resistant to the degradation caused by certain household chemicals, dust, and even in some instances, flames. They are meant to be waterproof to create an airtight and watertight seal on the duct on which they are used.

Share to Pinterest

We want to skirt our RV this winter with tarps. We will need a tape which can take minus 15 celcius temps, and not leave a residue or peel off the paint. Which would you recommend? Thank you.

Sorry, not too experienced with tarps.