R12 and R134a are older generation refrigerants that are no longer produced nor imported into the USA. That doesn’t mean to say that they’re no longer used.

There are many thousands of older air conditioning and refrigeration plants that use these refrigerants.

They’ll continue to work for many years, as replacement is costly.

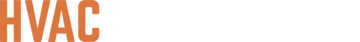

R12 vs R134a

These two refrigerants are very similar. They’re older generation refrigerants that have some serious environmental factors against them.

R12 was the first refrigerant created. It’s still one of the most efficient at cooling, but the destructive effects on the ozone layer and its very high global warming potential have made this environmentally an unwise choice.

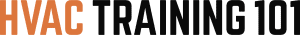

R134a was touted as the replacement for R12 until it too was deemed environmentally undesirable. In the case of R134a, it’s the global warming potential that’s an issue. It’s been labeled as a greenhouse gas, and its use is no longer supported.

R12

R134a

Pros

R12

Not toxic

Not explosive

Not flammable

Very efficient at cooling

R134a

Not toxic

Not explosive

Not flammable

Doesn’t contribute to the depletion of the ozone layer. ODP = 0

Cons

R12

Has a global warming potential (GWP) of 10900

No longer manufactured or imported into the USA

Has an ozone depletion factor (ODP) of 1 which is the highest possible

R134a

Has a global warming potential (GWP) of 1430

No longer manufactured or imported into the USA

Best For

R12

This is used in automotive air conditioning in older vehicles and domestic and commercial air conditioning and refrigeration.

R134a

This is used in automotive air conditioning in older vehicles and domestic and commercial air conditioning and refrigeration.

What is R12 Refrigerant?

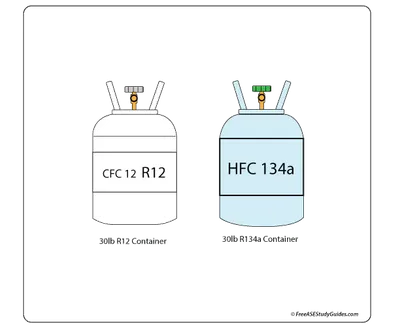

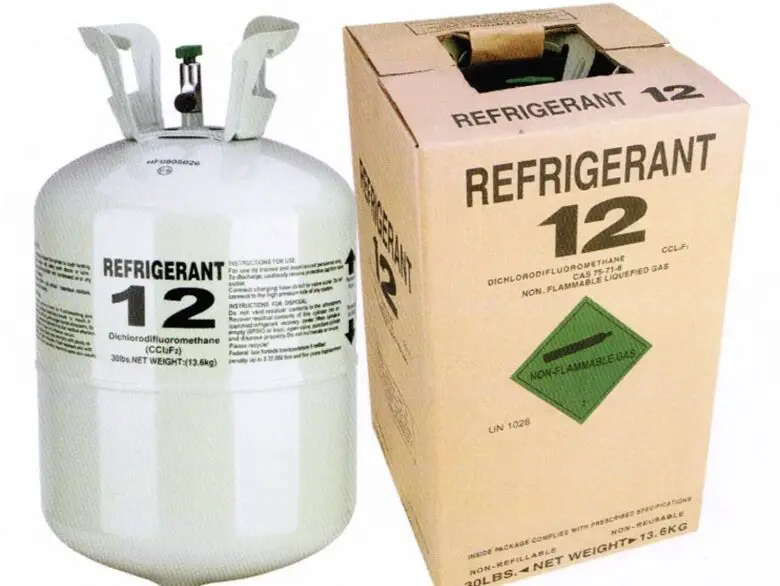

Refrigerant 12 or Freon 12 is colloquially known as R12. This chemical is an excellent refrigerant liquid. Its chemical name is dichlorodifluoromethane, and its chemical formula is CCl2F2. As this chemical has both chlorine and fluorine in its make-up, it belongs to the group of chemicals known as CFCs or chlorofluorocarbons.

R12 is well known as a refrigerant used in many applications as it’s non-toxic, non-explosive, and non-flammable. These properties make it very attractive for domestic, commercial, and automotive refrigeration and air conditioning. R12 is found in all kinds of refrigeration, ice makers, air conditioners, water coolers, transport refrigeration, and chillers.

R12 is recognized as a very stable compound, and it won’t break down under even the most stringent conditions, but if it comes in contact with flames or electrical heating elements, it breaks down into toxic components.

Being a CFC, this product depletes the earth’s ozone layer, contributing to global warming. This is measured using a factor known as ODP (ozone depletion potential). R12’s ODP is 1 (the highest rating). Hand in hand with this is the global warming potential (GWP), which measures the gas’s potential as a greenhouse gas.

R12’s GWP is 10,910. These are the major reasons that this product is now banned in many countries and replaced by other refrigerants that don’t have such a serious environmental impact.

What is R134a Refrigerant?

Refrigerant 134a, or R134a, was developed as an alternative to the CFC refrigerants known to cause environmental damage. In the last 10 years, new information has shown that this gas contributes to global warming. In many parts of the world, it’s now viewed as a greenhouse gas, and its use is discouraged.

R134a has an ozone depletion potential of zero and a global warming potential of 1430.

This chemical is tetrafluoroethane, and its chemical formula is CH2FCF3. As this chemical has carbon, hydrogen, and fluorine but no chlorine, it’s not dangerous to the ozone layer.

This product does contain dangerous chemicals such as methyl chloride and vinyl chloride, both of which are carcinogenic and may cause congenital disabilities. R134a belongs to the family of HFCs or hydrofluorocarbons.

R134a isn’t toxic, corrosive, explosive, or flammable, making it a good choice for air conditioning, but its cooling properties aren’t as good as R12.

R134a is still used in the automotive industry as a refrigerant and in other industries, such as pharmaceuticals, as a propellant. It’s found in domestic and commercial refrigeration and air conditioning.

Relevant Characteristics Between R12 and R134a

R12 vs R134a

Compare by tapping or clicking below!

Chemistry

R12

Dichlorodifluoromethane CCl2F2

R134a

Tetrafluoroethane CH2FCF3

Function

R12

Refrigerant for domestic & commercial use

R134a

Mainly used in the automotive industry but can be used as a refrigerant for domestic and commercial use

Performance

R12

Has excellent cooling properties and performs at a similar level to R134A

R134a

Has excellent cooling properties and performs at a similar level to R12

Cost

R12

∓US$25.00 per pound

R134a

∓US$5.00 per pound

Legality

R12

Legal to own

Illegal to vent

R134a

Legal to own

Illegal to vent

Similarities and Differences

As these two products essentially do the same job, there are many similarities between the two refrigerants. Their differences come mainly in their chemical make-up and environmental impact. Let’s have a closer look at these similarities and differences.

R12 and R134a Differences

Chemistry

The major difference between these two refrigerants is their chemical composition.

R12 is known as a CFC or chlorofluorocarbon, with a chemical symbol of CCl2F2. This means that this compound is made up of carbon, chlorine, and fluorine.

R134a is an HFC or tetrafluoroethane, and its chemical formula is CH2FCF3. This chemical has carbon, hydrogen, and fluorine.

Ozone Depletion Potential (ODP)

The ODP of a chemical is a factor that indicates the amount of degradation it’ll cause to the ozone layer that surrounds the earth and protects it from harmful radiation. The maximum value is 1.

R12 has an ODP of 1, meaning that it has the highest potential to destroy the ozone layer.

R134A has an ODP of zero, meaning that it has a negligible effect on the ozone layer.

Global Warming Potential (GWP)

The global warming potential is a factor that measures the amount of heat trapped by any gas when compared to the amount of heat trapped by the same amount of carbon dioxide. Carbon dioxide is deemed to have a value of 1, so the higher the compound’s factor, the greater its effect on global warming.

R12 has a GWP of 10,910, so its effect on global warming is over 10,000 times greater than carbon dioxide. R134a has a GWP of 1430.

Oils

All refrigeration plants use compressors to compress the gas returning from collecting heat, raise its temperature further, and compress it to facilitate cooling. All compressors require oils to lubricate the moving parts.

Tiny amounts of oil will inevitably find their way into the stream of gas. This means that the oil used in the system must be compatible with the refrigerant in use.

R12 uses mineral oil, but R134a won’t dissolve in mineral oil. This means that when using R134a, the compressor should be oiled with Polyalkylene Glycol or PAG oil.

There’s one type of oil that will work with both refrigerants. It’s called Polyol Ester Oil or POE oil.

R12 and R134a Similarities

Uses

Both of these products are refrigerants. They behave in the same way when used in any form of refrigeration or air conditioning plant. When they’re in a liquid state, they’ll remove heat from air passing over the pipes they’re in and slowly evaporate to form a gas. This gas is then cooled via environmental means, and the gas slowly loses heat and reverts to a liquid state.

R12 was used mainly in domestic and commercial refrigeration, while R134a was used mainly by the automotive industry.

All these industries still have old plants that use these refrigerants. Converting them is extremely expensive, and in many cases, replacement is the only option available.

Performance

Both of these compounds have similar cooling properties. R12 is considered to be superior in cooling to R134a.

Properties

Both of these gasses are very safe for use in all forms of refrigeration as they’re not flammable, explosive, or toxic. They’re also tasteless, colorless, and odorless.

Legality

It’s legal to own either of these gasses, but it’s illegal to vent them into the air.

Most countries frown on the use of these gasses due to their environmental impact. However, some old air conditioning units still use them. A qualified technician should vacuum out the gas and the refrigerant changed for something more modern and environmentally sympathetic.

Advantages of R12 Refrigerants

So, what makes R12 a good choice?

Safety

This product is safe to use in that it’s not toxic, flammable, or explosive. That makes it safe in terms of safety to use. These properties make it popular for domestic and commercial refrigeration.

Stable Product

R12 is extremely stable and won’t deteriorate operating under the most extreme conditions. However, it must be noted that it’ll disintegrate into toxic compounds when exposed to flame.

Works in a Wide Range of Applications

R12’s boiling point is -21.6°F or -29.8°C. This boiling point means that it’ll condense with moderate pressure, so applications can use a lower pressure condenser to achieve the same results. This ability has encouraged R12 in a wide variety of applications and over a wide range of temperature variables. It also means that rotary, centrifugal, and reciprocating compressors can be used with R12.

Oil Miscibility

R12 is miscible with mineral oil under any operating condition. This means that the tiny droplets of oil from the compressor that end up in the refrigerant will be returned via the compressor’s refrigerant; they won’t block pipes.

If the oil didn’t dissolve into the refrigerant, it would reduce the refrigerant’s ability to transfer heat. That’s not the case with R12, ensuring that the efficiency of the plant isn’t compromised.

Disadvantages of R12 Refrigerants

However, there are some drawbacks to using this type as well.

Environmental Damage

The most significant disadvantage of this product is the damage that it can do to the environment if it’s vented irresponsibly. While contained within a refrigeration system, this product is safe to use and poses no risk to the planet.

However, leaks do occur. When this happens, the chlorine in the product contributes significantly to the ozone layer’s depletion, leading to a lack of protection from harmful radiation.

Legalities

As this product is highly damaging to the environment, the environmental treaty signed in Montreal in 1987 stopped the use of CFC refrigerants, which included R12. All signatories to the Montreal Treaty stopped the production of CFC products. They’ve moved away from using R12 in favor of more modern, environmentally safer products.

It’s not illegal to own this product, but with it being withdrawn from use in so many countries, it’s no longer manufactured. This makes it expensive to purchase and adds to the attraction of replacing it with other greener products.

Advantages of R134a Refrigerants

R134a is a newer type of refrigerant that has some significant advantages.

Known Technology

One of the biggest advantages of using R134a is that it’s well known, tried, and tested technology. It’s been used in the refrigeration industry for a long time, so there’s a large body of knowledge established around the product. One can’t discount its drawbacks, but there’s a great deal of knowledge and information available on safely using the product.

Boiling Point

The boiling point of R134a is -15.34°F (-26.3°C.) This means that when exposed to the environment, it exists as a gas.

This is a highly desirable property as it means that the boiling point is always below the targeted temperature.

Environmental Impact

The major environmental impact of this refrigerant escaping into the atmosphere is its contribution to global warming. R12 has a global warming potential factor of 2400. This means that it’s classified as a greenhouse gas and will add to the current problems of heat not escaping the earth’s atmosphere.

R134a won’t damage the earth’s ozone layer.

Safety

R134a is safe to use as it’s not toxic, flammable, or explosive. These factors make it a safe product for a technician to work with. It’s a safe product for use in a variety of domestic and commercial environments.

Works in Many Applications

R134a was developed to replace R12, so it works over the same range of applications. R134a is used in many applications such as:

- Screw, roll, rotary, reciprocating, and centrifugal compressors for refrigeration and air conditioning

- Used in automotive air conditioning since 1994, and has been retrofitted to many older models as a replacement to R12

- Used in the plastics industry

- Used to remove humidity from compressed air in gas dusters

- Used in cryogenic particle detectors

Disadvantages of R134a Refrigerants

Although this type is better than R12, using this kind of refrigerant also has some problems associated with it.

Energy Usage

R134a isn’t as efficient in cooling as R12. This means when lowering temperatures to -7°C or below, there’s a noticeable drop in the plant’s ability to chill the air. This can significantly affect energy consumption as the plant will operate for longer, or a larger plant will have to be installed. In air conditioning units installed in motor vehicles, the system’s increased running time results in increased fuel usage.

Legalities

R134a is classified as a dangerous greenhouse gas that contributes to global warming. It belongs to a class of chemicals known as HFCs, and they don’t contain chlorine, so R134a doesn’t damage the ozone layer.

Because of this product’s greenhouse gas attributes, its manufacture has been banned in the European Union since 2011, and motor manufacturers stopped using it in motor vehicle air conditioning at that time.

As this gas has such an effect on the environment, the EPA (Environmental Protection Agency) has strict guidelines for its use. Technicians must capture and recycle R134a safely, and the gas must be disposed of by following the EPA guidelines. All leaks in systems using R134a must be repaired within 30 days.

Only licensed air conditioning companies and technicians may purchase this refrigerant. These guidelines are strictly enforced, and contravention of them can lead to severe penalties being imposed.

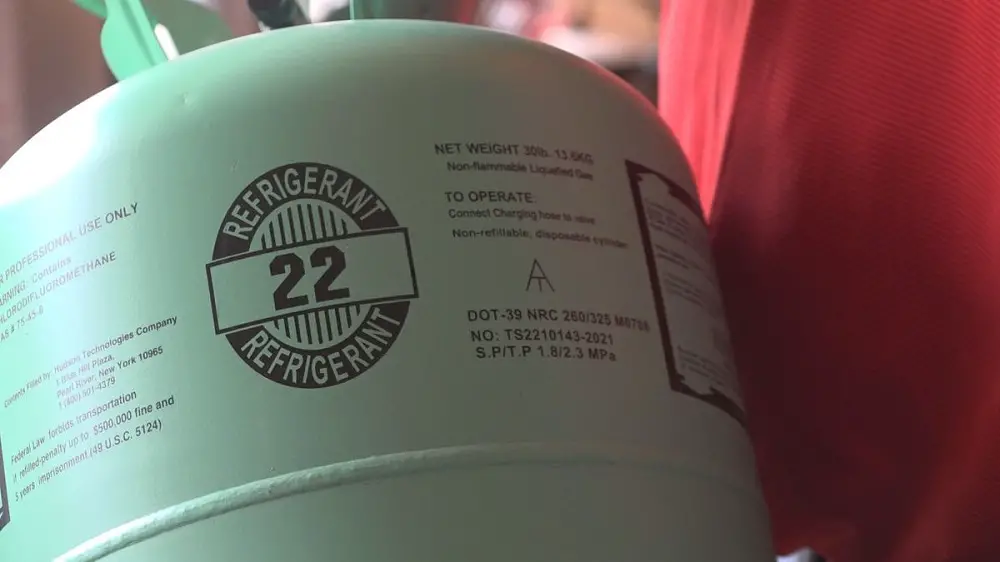

What About R22?

R22, or to give it its proper chemical name, chlorodifluoromethane (CHCIF), is a colorless, odorless, non-toxic, non-flammable alternative to older refrigerants. Unfortunately, this product still contains chlorine. While the use of this product is steadily increasing in many developing countries, it’s now banned in the USA and, since 2020, is no longer manufactured or imported to the USA.

This product was developed to overcome the old CFC refrigerants’ problems as it has an ozone depletion potential (ODP) of 0.055. In contrast, older CFC refrigerants had an ODP of 1. In addition to it having a low ODP, science has proven that R22 is also a strong greenhouse gas and has a GWP of 1810, indicating that it’s 1810 times more powerful than carbon dioxide in contributing to global warming.

In today’s world, the combination of its ozone-depleting ability and its contribution to global warming makes this product a major issue for many countries.

As the manufacture of this product is now banned, the costs associated with it will inevitably rise. Unfortunately, converting existing air conditioners that use R22 to use new refrigerants isn’t easy. It’s been likened to trying to convert a petrol engine to run on diesel. Compete replacement may be the only answer.

It’s unlikely that air conditioners or refrigeration plants will be converted from R12 or R134a to R22, but it can be done if reclaimed R22 refrigerant can be located. It’s better that this is done by professional technicians as venting any of this gas into the atmosphere is environmentally damaging and illegal.

When Would I Choose R12 Refrigerant?

It’s improbable that any new installation will be built that uses this refrigerant as its use is deemed highly undesirable in many countries and international environmental treaties discourage its use. Many existing installations continue to use the product.

Automotive

Many older automotive systems still use R12, and as you’re still able to purchase individual small cans of this refrigerant via on-line marketplaces, its use in many classic motor vehicles will likely continue. The conversion to more modern refrigerants will require a replacement of the system, which will cause issues in terms of originality when showing this type of vehicle.

Domestic Refrigeration

This product is non-toxic, non-flammable, and not explosive, so it’s extremely safe to use for domestic refrigeration. The only time this product will be unsafe for humans is if it’s exposed to flame, when it breaks down into toxic substances or if it’s discharged into the air.

Older fridges and air conditioning units that use this refrigerant will still work efficiently, and converting them to more modern refrigerants will be difficult and unrealistically expensive.

Commercial Refrigeration

Many commercial enterprises that run large chillers or transport companies running reefer trailers or containers have used R12 as it’s a highly efficient refrigerant that provides excellent cooling.

It’s likely that these plants, which will be expensive to convert, will continue to use R12 with careful maintenance.

When Would I Choose R134a Refrigerant?

Any new installation of refrigeration or air conditioning won’t use R134a as a refrigerant as the production and importation of this gas to the US has been banned. That doesn’t mean to say that there are still many thousands of existing installations that are running refrigeration plants using this refrigerant to cool them.

Automotive

R134a is the most commonly used refrigerant to convert automotive air conditioning away from the destructive R12. It’s possible to convert from R12 to R134a without replacing the system’s components, so when R134a was brought out, it seems to be a good match to many automotive air conditioning issues. Many vehicles that contain this type of refrigerant will continue using it.

Domestic Refrigeration

Like R12, this product is non-toxic, non-flammable, and not explosive. These attributes make it very attractive for domestic refrigeration. The effect that R134a has on global warming makes this gas an unattractive product to many technicians.

Many existing fridges and air conditioning units still use this refrigerant and work very efficiently. Providing they don’t leak, they’re no risk to the environment.

Commercial Refrigeration

As R134a was touted as the replacement for R12, and the conversion of the refrigeration system to run R134a was relatively painless, many commercial installations use this refrigerant. Converting these plants to run modern refrigerants will be extremely expensive, and in many cases, mean complete replacement; these plants will likely continue to run for many years.

Bottom Line

R12 and R134a are older types of refrigerants that are considered to be dangerous to the environment today. R12 is highly destructive of the ozone layer, and R134a is over 1,000 times more dangerous in terms of global warming than carbon dioxide. Both of these refrigerants won’t be used in new air conditioning or refrigeration plants, but they’ll continue to be used in existing plants and the automotive industry.

People Also Ask

As these refrigerants are slowly phased out, there are still many questions that people have about them. Here are a few of the more common questions.

R134a replaced R12 from 1994 onwards. Motor manufacturers in the USA used R134a in air conditioning systems for new cars from 1994.

The simple answer is you can’t. The biggest problem that you’ll have is the oil in the system. R12 will completely dissolve in mineral oil, but R134a won’t. This means that the mineral oil in the system won’t dissolve. The system will accumulate a type of acidic sludge that will eventually destroy the system.

If your car was produced after 1994, it likely has R134a used as the refrigerant. Another way to check is to look at the air conditioning connectors. R12 connectors were of the screw type, while R134a has push-on connectors similar to air tools. There should also be a blue sticker somewhere on the system telling you the date the system was converted.

R134a was the replacement refrigerant for R12. However, it’s been shown that R134a is as destructive to the environment, and newer refrigerants have been created to overcome this problem.

No, it’s not possible to mix these two refrigerants. The problems that arise are related to the oils used in the system and the fact that they have different charge weights and different boiling points. In addition to this, federal laws prohibit the topping up of an R12 system with R134a and vice versa.

The biggest giveaway is the air conditioning connectors. R12 systems use screw-on connectors, while R134a systems use push-on connectors similar to those used in air tools. Also, look for a blue sticker that gives the date of conversion. If you’re still uncertain, go to a trained technician who’ll tell you what refrigeration you have.

Yes, there will be less refrigerant by weight. A simple rule of thumb conversion would be to take the amount of R12 refrigerant your system requires, in pounds, and multiply by 0.9 (your answer should be 90% of the R12 value). Then subtract 0.25 pounds. This should give you a rough idea of how much you’ll need.