Are you having trouble deciding which ductwork type is suitable for you? Or maybe you barely understand the fundamentals that make them different from each other.

Honestly, it can get very confusing, and sometimes the information is all too much to take in. We’ve decided to make it easier for you. We’ve collected all the information you might need in making your decision, from the small similarities and differences to the vital details that you’ll need to know and consider.

Let’s start with the differences between duct board and sheet metal:

Duct Board vs Sheet Metal

Duct Board

Sheet Metal

Pros

Duct Board

It’s easy to fabricate and easy to replace

It produces very little noise when under pressure

The duct board is affordable and cheap to install and maintain

Sheet Metal

It’s an excellent corrosion-resistant product

Sheet metal is highly durable and can last for years

When installed properly, it’s energy-efficient and doesn’t cause a lot of problems. It’s worth having in the long run

Cons

Duct Board

It has restrictions where dust particles and dirt are trapped

It gets damaged when in contact with water or excessive moisture

The duct board is less durable than sheet metal and can be easily damaged

Sheet Metal

Sheet metal is very costly to purchase and to install

You can fabricate it quickly, and you will need professional help

If there are problems done in the installation and they go unnoticed for a long time, the consequences might be catastrophic

Best For

Duct Board

Duct board is suitable for people who need an affordable alternative and those who have basic knowledge of installing and fabricating wherever required.

Sheet Metal

Sheet metal is suitable for anyone who can afford it and also great for work buildings. It’s costly and requires proper installation, and it needs someone who can ensure it’s correctly done.

What is Duct Board, and What is Duct Board Used For?

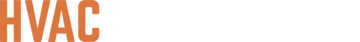

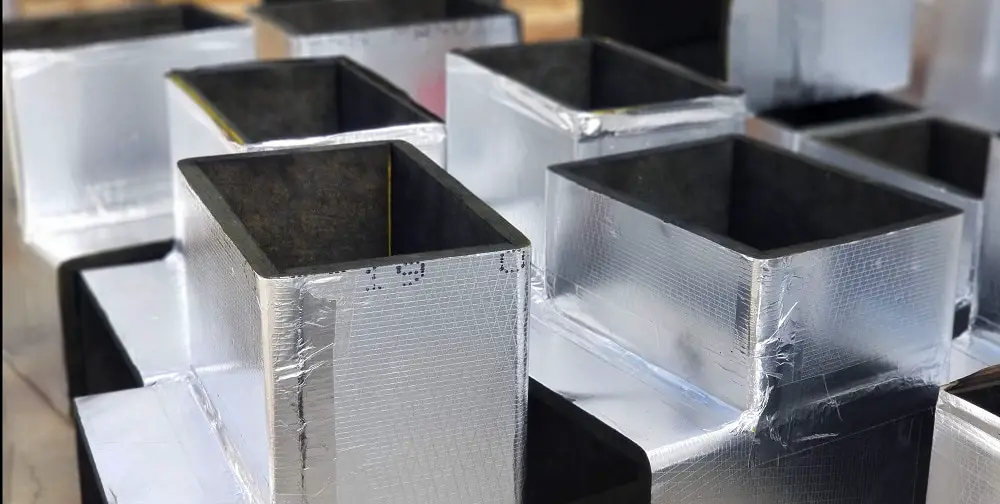

A duct board is commonly used for residential or light commercial heating and cooling systems in place of the metal duct. A duct board is a pressed, semi-rigid fiberglass sheet with a binder.

It’s manufactured in sheets that are fabricated into a rectangular shape as a traditional sheet metal duct. Duct board insulation is a more silent alternative to a metal duct because it lacks metal-to-metal contact and metallic components in general.

The advantage of using a duct board is that fabrication is faster and less labor-intensive. It has certain advantages over metal installations that contractors prefer.

To cut the duct into square or rectangular shapes, expensive machinery isn’t needed because you can use special knives. It also produces very little air noise when under pressure, and the material is airtight and easy to seal.

Duct board installations have some downsides as well. The fibrous material can erode into the airstream because the duct board consists of rigid insulation.

The duct board should never come in contact with water. Mildew and mold are produced in a wet duct board, so this means that duct board should only be used in places where it won’t be exposed to damp conditions.

What is Sheet Metal, and What is It Used For?

Sheet metal is a material commonly used in construction and other industries. An industrial process forms it into thin, flat pieces. It can be cut and bent into various shapes and is one of the fundamental forms used in metalworking.

Sheet metal is low in weight and gauge and is also very affordable. It creates a very durable surface because it can be formed into many shapes. This aspect makes it ideal for use in different climates and different weather conditions, including extreme hot and cold temperatures.

Some of the biggest dangers of working with sheet metal are the potential for cuts and lacerations. Although pieces of sheet metal are typically smoothed out on the sides to reduce cuts, their edges may be sharpened by factory fabrication.

Another potential danger is skin burns because, unlike wood, sheet metal is highly conductive to thermal energy.

Relevant Characteristics Between Duct Board and Sheet Metal

Duct Board vs Sheet Metal

Compare by tapping or clicking below!

Cost

Duct Board

Affordable. It doesn’t last as long as metal.

Sheet Metal

Highly expensive because it lasts longer.

Energy Efficiency

Duct Board

High energy efficiency

Sheet Metal

Low energy efficiency

Flexibility

Duct Board

Duct boards are only flexible in the sense that they can be altered here and there. It’s not a difficult product to work with.

Sheet Metal

Sheet metal has no flexibility and requires professional help most of the time.

Installation Requirement

Duct Board

Duct boards are easy to install, and homeowners can do their installations. Required tools are costly.

Sheet Metal

Requires professional installation.

Noise Reduction

Duct Board

There is less noise produced.

Sheet Metal

Sheet metal tends to create noise and sounds.

Insulation Ability

Duct Board

Duct board isn’t the best heat conductor because it’s wood.

Sheet Metal

The insulation of metal is essential because it’s a better heat conductor than wood.

Friction Rate

Duct Board

Standard friction rate

Sheet Metal

Standard friction rate

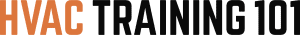

Similarities and Differences

Duct board and sheet metal are different and similar in certain aspects, but one might be preferable over the other. Without a doubt, both products are suitable for both residential and commercial use.

If you still have doubts about which is best for you, let’s explore the differences and similarities to understand each product better.

Duct Board and Sheet Metal Differences

Installation Requirements

Sheet metal requires technical knowledge and professional installation, while duct board requires little to no professional help. After some time, problems arise due to overlooked factors in most installations of duct board.

This makes sheet metal the most guaranteed and highly used in buildings, not to say that you can’t hire professional help for your duct board installation. It would save you future problems.

Cost

The difference in cost is due to sheet metal being more durable than duct board. It’s mostly used in office spaces and is highly recommended. Duct boards are more affordable and easy to use in DIY projects.

Insulation Ability

Metal is a better heat conductor than wood, which makes sheet metal better in terms of insulation than duct board. However, there are types of duct insulators that can be effective when used on duct boards.

Bottom Line

There are differences in noise and safety between the two products, but there are specific alternatives to accommodate the differences.

Duct Board and Sheet Metal Similarities

Effective

Both duct board and sheet metal are practical and efficient despite their differences. Both are great products to use and are highly recommended. Both work in residential and workspaces.

Durability

If a duct board is well taken care of, it can last for several years. Well cared for duct boards will need to be replaced less often.

Insulation

Both products can be insulated, although in different ways. The best way to insulate them is to do it on the outside so they won’t disturb the air supply or trap any dust. This will also reduce maintenance.

Bottom Line

Sheet metal and duct board have a variety of similarities. Their differences are what make them stand out. Overall, they are both great products.

Advantages of Duct Board

There are various advantages of using duct board, which makes it the most frequently used alternative:

- Duct board is relatively cheap and is a less expensive way to pay for ducts. Unlike sheet metal, almost anyone can afford it.

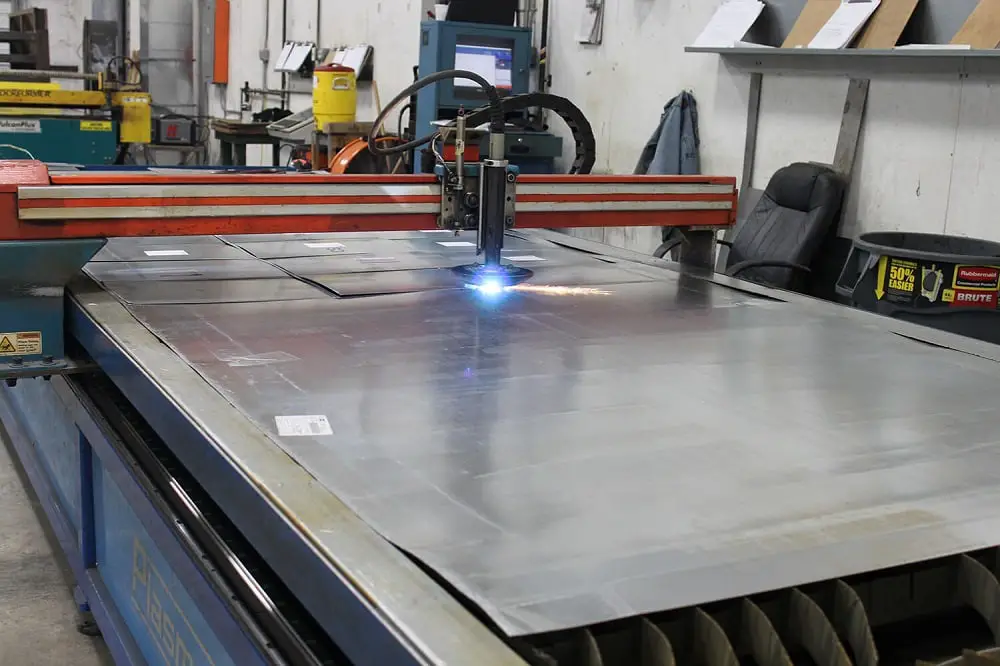

- It can be easily fabricated and easily replaced. Although the tools to fabricate are expensive, the process itself is less costly and faster. It demands less intensive labor, less skill, and, therefore, fewer costs. Special, affordable knives are also available for fabrication.

- Unlike sheet metal, duct board doesn’t produce any noise when under pressure. There will be no popping sounds or noise caused due to the circulation of air. This system is ideal for residential areas.

Advantages of Sheet Metal

Investing in the right sheet metal product has benefits such as:

- Sheet metal can last for years. Despite its maintenance, it offers a permanent solution. You won’t have to change or replace it unless there is a need. It’s highly durable and robust.

- Sheet metal is an excellent corrosion-resistant product.

- It can be insulated differently, such as being wrapped on the duct’s outside to reduce restrictions on the duct’s inside and reduce places for dust and particles to be trapped.

If sheet metal ducting is lined on the inside for installation and dust particles become trapped in the exposed part of the installation, there will be restricted airflow; chances of mold or mildew will increase. The best way to insulate it would be on the outside, keeping the inside working efficiently. - It’s available in different gauges for strength against abuse, and it can be produced in many shapes or sizes to fit unusual locations. There is excellent airflow, and it resists damage from water, unlike many other products. Sheet metal can also be fabricated and altered if need be. This way, there isn’t a limit to how it’s supposed to look.

Disadvantages of Duct Board

Using duct board has considerable disadvantages:

- Duct board is less durable than sheet metal due to its weak structure, and it’s vulnerable to critters chewing the ducting. It’s also susceptible to moisture. When exposed to water, the duct board can be damaged. Wet duct board produces mildew and encourages mold growth.

To thrive, mold needs an organic food source, low light levels, and water. When a duct board is installed in a wet crawl space, it creates an environment that mold needs to grow. The fiberglass provides moisture and provides a breeding ground for mold spores. - It has restrictions and places for dust and particles to be trapped in the exposed part of the installation, which makes it a very cheap system.

- Duct board consists of a compressed fiber plus with a reflective paper bonded to the outside two different thickness levels of insulation. This restricts airflow, which holds moisture and becomes fragile, increasing the chance of mold or mildew.

The duct board consists of a rigid material, and fibrous material can erode into the airstream. Although the duct board can be bought with a treated surface that resists erosion, it’ll be harder to fabricate and will cost more to install. - In some instances, the duct board will need to be replaced if it gets easily damaged. In terms of maintenance, it might need professional cleaning.

Disadvantages of Sheet Metal

Sheet metal has advantages such as:

- Sheet metal installation and fabrication are generally more labor-intensive and very costly. You can’t fabricate your sheet metal very easily or in the comfort of your own home. You’ll need to take it to qualified people, and it might cost you a lot.

- The installations are almost always hidden, which is the problem. There are never any telltale signs like water stains to indicate a problem of leaks or improper venting. If it’s somehow determined that there’s a problem, it’s challenging to isolate exactly where it occurs.

If there’s a problem with your system or installation, the consequences can be catastrophic. If it leaks or there is a poorly installed duct that prevents adequate ventilation, there could be potential health issues.

This can also damage equipment. Therefore, fittings and installation of sheet metal ducts must be expertly fabricated, installed, and inspected. - In case of any damage, sheet metal can be expensive to maintain or fix. You might need to replace all of it. If it needs to be altered, you’ll pay a lot of money due to the labor-intensive work.

What About Metal Plenums?

A metal plenum is an air distribution box attached directly to the supply outlet of an HVAC unit that heats or cools space. Its critical function is to bring in, distribute, and remove air.

Connected to the plenum is the ductwork that distributes the heat or cool air to the room. There is also a return plenum that removes the air in the room.

Plenum compartments are found in buildings, either above suspended ceilings, in the gap between the ceiling and the floor slab, or below the raised floor in the gap between the raised floor and floor slab. The plenum gives good flexibility to the layout of buildings.

There are various reasons why people are now deciding to use plenum.

As plenum space efficiency in ventilation increases, there is reduced noise and improved energy efficiency. There is also a stable balance of airflow and high impermeability.

A metal plenum box equalizes the air pressure to even its distribution. It also saves on space if there’s limited ceiling space. It’s easy to install and is found in different sizes to accommodate different HVAC systems. They have more benefits in the long term than other options.

Unlike ducts, a plenum box never has a problem with uneven air distribution. A pressurized plenum combined with a high induction diffuser face like AXO, NEX, or PLAY solves this problem.

An acoustic liner added to the plenum boxes annotates the sound coming from the duct and equipment. The bottom line is metal plenums are a wise investment with improved energy efficiency, reduced noise, and easy installation in limited space.

When and Why Would I Use a Duct Board?

Sometimes this material makes the most sense, including:

Tight Spaces

For specifications where weight or space is restricted, a phenolic pre-insulated HVAC duct is ideal. Compared to traditional galvanized pre-insulated ducts, a pre-insulated HVAC and pre-insulated panels offer high performance, are lightweight, and create robust ductwork systems.

The system only requires a single six-installation process. This makes it a high-speed operation for projects in which time is critical and also saves on space and cost.

Less Noise

Unlike metal duct systems, duct boards are usually much quieter.

Metal duct systems, even the ones adequately installed, usually have vibration noises, as well as popping sounds, from the metal expanding and contracting with the temperature change. The fiberglass duct board system typically has less flow noise when adequately sized.

There are hardly any noise complaints. They’re also easy to install and fabricate and easier to hang than metal ducts.

No Water Exposure Places

If you have a place where you’re sure that your duct board won’t be affected by any moisture, it’s an excellent option to pick. When the duct board is exposed to moisture, mold is likely to grow. This is an affordable option and even better for places where there will be almost no damage to the duct board.

When and Why Would I Use Sheet Metal?

There are times when sheet metal is required or is more desirable. Here are some situations where you’d want to use this material.

Preventing Leakage Through the HVAC System

When installing ducts and you want them to work effectively and efficiently, you need duct designs that can prevent leakage when moving air through the HVAC system. You could use galvanized mild steel and aluminum. Either of these materials will effectively maintain the air quality in any space with minimal risk of leakage.

For building ducts, galvanized mild steel is often used due to the material’s zinc coating to prevent corrosion and rust build-up. Aluminum material facilitates easy installation, true to its lightweight construction. These two systems are among the most energy-efficient. The type of ducting system will depend on the building and the size.

In Complicated Spaces

Sheet metal is ideal for complicated spaces because it’s available in different gauges and is produced in different shapes and sizes to fit unusual locations. It can also be fabricated. If adequately fabricated, there will be long-term problems and no complications. There isn’t a limit to what sheet metal should look like; it can be altered as necessary.

The ductwork used needs to be flexible and yet strong. It shouldn’t interfere with the air space.

In Workspaces

Sheet metal is ideally used in workspaces or commercial buildings because of its easy installation. It can accommodate large spaces, and it involves intense ductwork, which makes the overall structure trustworthy for office spaces. It’s less likely to develop problems and is easy to maintain.

Various types of ductwork systems could be used. It all comes down to the factors that need to be considered about the area.

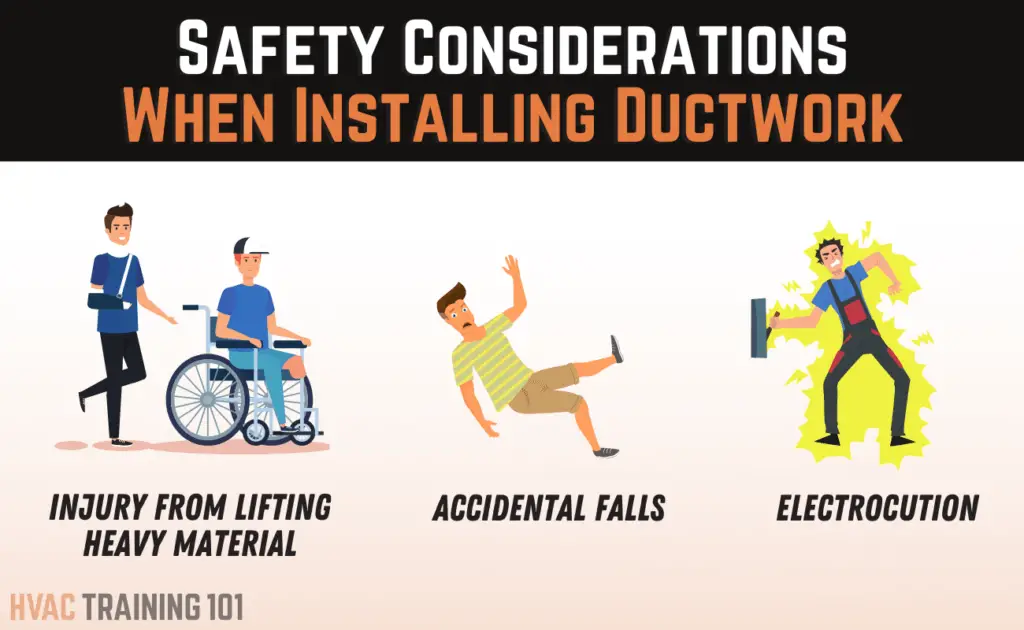

Safety Considerations When Installing Ductwork

No matter what you choose, be sure to put safety first when installing your ductwork.

Injury From Lifting Heavy Material

Depending on the type of ductwork used, you might find yourself having to lift heavy material. During installation, you might be required to manually raise and carry material that can cause injuries to your ligaments, sleeves muscles, and lower back. This might cause sore spots. Such injuries are most likely to occur due to repeated movement over the day and if you’re not used to carrying heavy equipment.

Accidental Falls

While installing your chosen material, you may be required to work at heights. Typically, most people don’t have the necessary protective gear.

You have to avoid slips and falls because some accidents may prove to be fatal. You should get professional help to install your ductwork or prepare safety measures so you know you’re safe.

Electrocution

Generally, ductwork systems are installed in proximity to electrical wiring. During ductwork maintenance and installation, you might come in contact with electricity and suffer electrocution.

You need to be fully equipped with the right protection gear in case you’re exposed or the electric wiring isn’t properly isolated.

Bottom Line

The bottom line is duct board and sheet metals are excellent products, no matter which you choose. It all comes down to which one works best for you.

Sheet metal might be a bit costly, but it’s highly durable and lasts for years. With excellent installation, it becomes a perfect permanent solution, and you don’t have to spend much maintaining it. It also requires professional installation because it can’t be easily fabricated. If low installations are done, dire problems will arise in the future.

Duct board, on the other hand, is more affordable and not as durable as sheet metal. If well taken care of, the duct board can last for years as well but will eventually need to be replaced. It has an easy installation system, and it can be fabricated easily. The duct board might have problems if not installed correctly, but it’s easy to replace.

People Also Ask

Below are a few frequently asked questions that might help you decide which product is best for you.

How your health will be affected depends on the type of exposure and on the fiber size. At a minimum, fiberglass might cause an acute physical irritation to the eyes, skin, and upper respiratory tract. Usually, there are no long-term health effects.

Small duct board fibers might be breathed into the lungs, but your body will naturally remove them from itself through coughing, sneezing, and other defense mechanisms.

Duct board can be cleaned through well-controlled brushing of duct surfaces. Vacuum cleaning can be used as well as soft bristle brushes.

Mold can grow inside the hard surface of the duct board. The ducts can also become infested with vermin or clogged with excessive amounts of dust and debris.

A duct board is a manufactured fiberglass sheet used in heating and cooling systems. The sheets are cut into squares that are connected and provide a path airflow in the heating and cooling system.

It’s available 1” , 1.5” , or 2” and with the dimensions of 4′ x 8′, 4′ x 10′ or 8′ x 10′. They have R values of either four, six, or eight.